Axial design examples

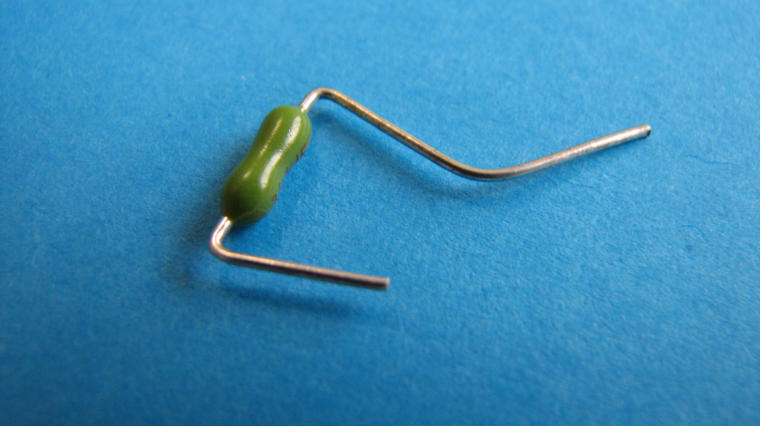

Dear customers, below you will find an extract from our axial design examples. They are certainly not limited to the respective component type. Bending form 1: • Cutting and bending from 0.4 - 1.3 mm lead diameters • Body diameter max. 35 mm • With a printed circuit board thickness of 1.6 mm, the lead penetration depth is then 1.5 ± 0.1 mm (standard) • Distance between body and bending radius depends on the width of the used bending finger • Options: 1.0 …1.2 …1.5 mm (standard = 1.5 mm) Bending form 2: • Snap-in cutting, bending, and crimping • Lead diameters from 0.4 - 0.9 mm • Body diameter max. 35 mm • With a printed circuit board thickness of 1.6 mm, the lead penetration depth is then 1.5 ± 0.1 mm (standard) Bending form 3: • Standoff cutting, bending and crimping • Lead diameters from 0.4 - 1.3 mm • Body diameter max. 35 mm • With a printed circuit board thickness of 1.6 mm, the lead penetration depth is then 1.5 ± 0.1 mm (standard). Bending form 4: • Upright / crimping shapes: snap-in, standoff and straight cutting • Lead diameters from 0.4 - 0.9 mm without tool exchange • Body diameter max. 5 mm • With a printed circuit board thickness of 1.6 mm, the lead penetration depth is then 1.5 ± 0.1 mm (standard)

Bending forms

Special forms